Downstairs from our spa-like waiting room and airy treatment rooms, there’s magic happening. Enter our milling lab, where the power of technology meets the human touch of artistry.

Four laboratory technicians work as a team to create the foundation for the beautiful dentistry that we are able to produce upstairs. Putting their combined decades of experience to work, they create wax mockups to envision the final result that we are looking to create. We transfer the beautiful rendering to the patient’s mouth for a perfect end product. They are truly artists.

While most dental practices rely on remote milling labs across the country to create dental prosthetics, our on-site milling unit and lab provides meaningful advantages for patients. Having an in-office milling unit and lab offers tighter control of work quality, increased oversight to ensure a perfect fit and a significantly more efficient process for our patients, saving time and stress.

CEREC: Crowns in a day

The technology centerpiece of our milling lab is the CERECR digital dental CAD/CAM technology. CEREC (Chairside Economical Restoration of Esthetic Ceramics) technology brings together digital impressions, diagnostic tools, design software and online communication to actually manufacture customized dental prosthetics including ceramic crowns, bridges and veneers.

This technology enables us to provide our patients with durable, esthetic, well-fitted, high-quality, all-ceramic crowns in a single visit. The CEREC system can create single crowns, multiple crowns, implant crowns or even bridgework.

The CEREC CAD/CAM process

- In the exam room, the dentist uses a state of the art, digital 3D camera to create a digital image of the tooth to be repaired, as well as the adjacent and opposing teeth. (This means there is no need for the goopy impression material!)

- After the preparation of the tooth, the CEREC CAD software creates a proposed initial design of a crown to replace the compromised tooth.

- Using the CEREC CAD software, the doctor modifies the proposed design, customizing the shape of the crown to accommodate adjacent teeth, structures and spacing. The doctor also designates the shade and translucency of the crown to match your natural teeth.

- The completed design and resulting digital image are transmitted electronically to the CEREC in the milling lab.

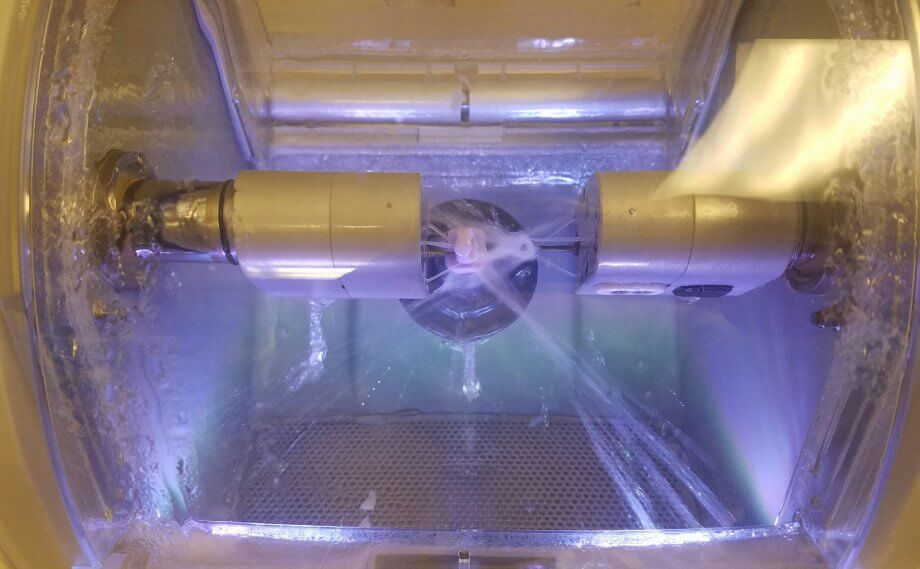

- The lab technician selects a porcelain block of the appropriate size, color and translucency and inserts into the CEREC CAD/CAM chamber.

- Based on the digital design, the CEREC mills the inside and outside of the crown from this solid block of material, through subtractive manufacturing. The process takes about 15 minutes.

- The rough-milled crown is tried on to assess the fit and to make any minor adjustments needed.

- After the fit is perfected, the crown is returned to the lab and the surface is smoothed and polished. Custom staining, glazing and colorization is then applied to match the patient’s natural teeth.

- The crown is heated to over 1500 degrees Fahrenheit in a sintering oven (like a kiln); the glass fibers are fused, transforming the crown into a hardened state with the appearance of a natural tooth.

- The final step takes place in the exam room where the porcelain crown is cemented and care instructions are provided to the patient.

CEREC patient benefits

- New customized crown in a single visit

- No need for impressions (goopy material can cause gagging)

- No temporary crown needed

- Minimal scheduling disruptions

- Custom color matching

- Greater customization with lab technicians on-site

- Less stressful experience

- Fraction of the time required

- No follow up visits needed

Request an appointment